Here

are five basic considerations for building a Metal and Steel deck and Joist:

1. Choose Your Deck Type - there are several types of decks you can have for

your home. An outdoor patio deck can be attached to your home. A convenient

location for your outdoor patio deck could be attached to the family room or

kitchen. How to build a deck that is a destination deck? A destination deck

would typically be located in a special place with a view and would not be

connected to your home. You might have a winding path that would lead to the

destination deck. How to build a deck that is a connector deck? A connector

deck is several smaller decks of any shape or size connected to each other with

pathways.

2. Consider Your Deck Activities - when building a wood deck, will your deck be

a place to grill and barbecue? Are you going to have parties and entertain

family and friends? Is your deck going to be a quiet place for lounging,

reading or enjoying your favorite beverage? Will you have a luxurious hot tub

on your deck? To increase privacy, will you have landscaping, plants or trees

around your deck? Take some time and think through how to build a deck that

will perform the way you want. Go online and buy a good book on planning and

building a wood deck.

3. Decide Your Deck Size - if your house and backyard is smaller and you won't

entertain large groups, you likely don't need a large deck. Too large a deck

can actually make the house appear smaller. Keep it simple, but add an angle or

two to the deck design if you want. When building a wood deck, you can divide

the deck into two areas - one area for lounging and sunning and another section

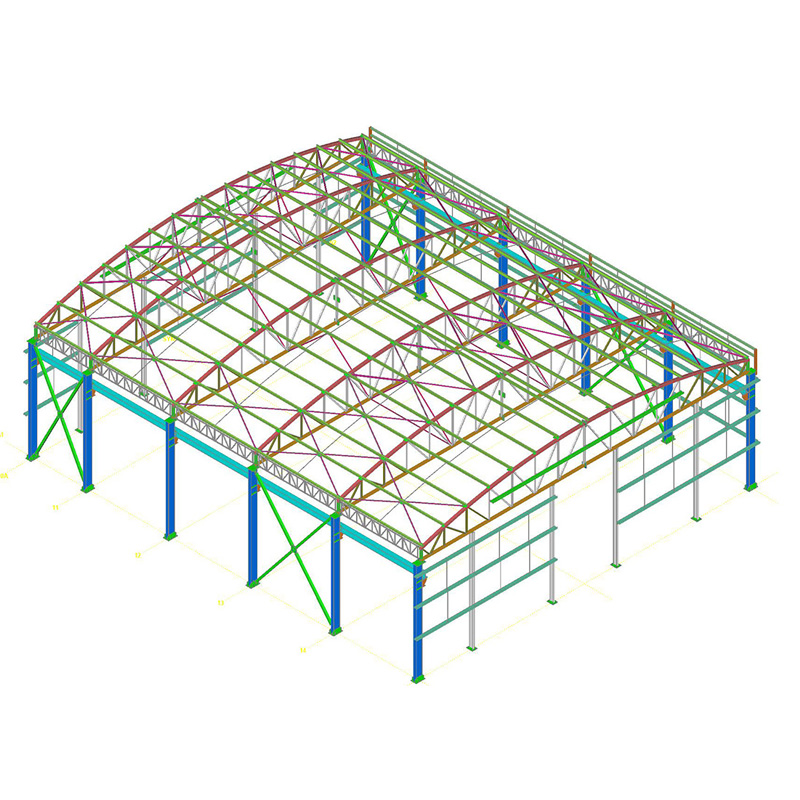

for cooking Joist and Deck Detailing and Designing

service and dining.

4. What Deck Materials Will You Use - if you will be building a wooden deck,

there are several structural parts. Your deck may need concrete footings that

extend below the frostline if you'll have freezing winters. If your deck will

be on sandy soil, you may need to build larger footings that will support the

deck posts or beams. The posts can be 4x4 lumber which is generally strong

enough to support the deck. If your deck is above ground, you may be required

to use 6x6 structural posts. The deck beams will rest horizontally on the posts

and will support the deck joists. Deck joists will be spaced horizontally every

12, 16 or 24 and will support the decking boards. The decking boards are the

floor of your deck that span from joist to joist.

5. Design and Build It Yourself or Hire a Professional - unless you live in a

very rural area, there will probably be building code requirements, permits and

inspections needed when building a wooden deck project. Contact your local

building official to see what is required in your area. One major advantage to

having qualified professionals help is that they understand the legal side of

how to build a deck and can help ensure building code requirements are met.

One of the best ways to understand how to build a deck is to view wood deck

plans that have been built many times. Seeing attractive deck plans can give

you deck building ideas that will simplify your planning and design. Global

Detailing and Designing

There are numerous designs that can be applied into your desired deck railings

aside from safety features. Traditional railings are the easiest to construct

and place while other variations may need the help of an engineer to build to

ensure their safety. It is very important that a railing meets the safety

standards because it is use keep individuals safe.

MATERIALS NEEDED FOR BUILDING A DECK RAILING

The materials that you need to acquire for your project are one by three inches

outdoor stock, one by two inches outdoor stock, sandpaper, nails, screws and

bolts and glue that is typically used for carpentry.

TOOLS

The tools needed in building your platform railings are a drill with complete

bit set, saw, hammer, marker, paper, level, chalk line and yarn or string.\

STEPS

This kind of system is a very simple to place down and construct. The vertical

parts of your project are called stiles. Carefully cut as many as you needed to

the length that the building code in your area requires. Although there are

visible differences that you should follow, most building codes require about

four inches of space in between the stiles.

If you are constructing a traditional railing, you have to decide whether you

will be placing the stiles just to the elements of your deck rail or to the

joist below your platform. Divide the stiles to your local building height

codes. Divide the outside portion of the upper part of the stile at any angle

that you want for additional design. Place a pair of screw holes into the

divided part of the stile-one at upper portion and the stile's countersink.

If the posts place in the corner of the platform does not reach the upper

portion of the deck, you should trim the deck in order to continue placing the

post. But you can just utilize a bigger stock for your corner post.

Utilize the lower part of the joist as a pattern when placing the stiles. A

hole that is pre-drilled in the structure is appropriate for nails that needed

to be galvanized. Make a jag for spaces in between the stiles and secure them

in place with a nail.

Some

of Our Key Joist and Deck Detailing and Designing Services are: Joist &

Deck Detailing

Joist

And Deck Detailing Services

Vulcraft Standard Joist And Deck Detailing Service

Provider

New

Millenium Standard Joist And Deck Detailing Service Provider

Structural

Steel Detailing Services

Joist

& Deck Design & Detailing

Joist

And Deck Detailing Services

Structural

Bar Joists Drawings Services

Open

Web Steel Joists K-Series

Dlh-Series

And Lh-Series

Deep

Longspan And Longspan Steel Joists

Single,

Double, Parallel, One Way And Two Way Pitched Cords

Joist

Detailing

Floor

Joist Drawings

Steel

Floor Joist Drawings

Bar

Joist Designs Drawings

For

More Information please visit us at https://www.globalsteeldetail.com/steel-deck-detailing.html and https://www.globalsteeldetail.com/steel-joist-detailing.html

When you reach approximately ten inches, place another support for the header

portion. This board will help stabilize the upper portion of the stiles and is

usually ten inches long. As you continue to place stiles in your railings,

start to install the header board. This will connect the whole thing together.

Put the drill into the hole that you previously drilled at the stiles and

continue placing the hole into the joist.

Connect the stile to board with a screw. For additional strength, place nails

that are galvanized into the cap and header area. Connect the two parts with a

nail. For a finishing touch, you can either varnish or paint your project. If

you divided the stiles of the railings, it will be simpler to varnish before

you put them together.

Comments

Post a Comment